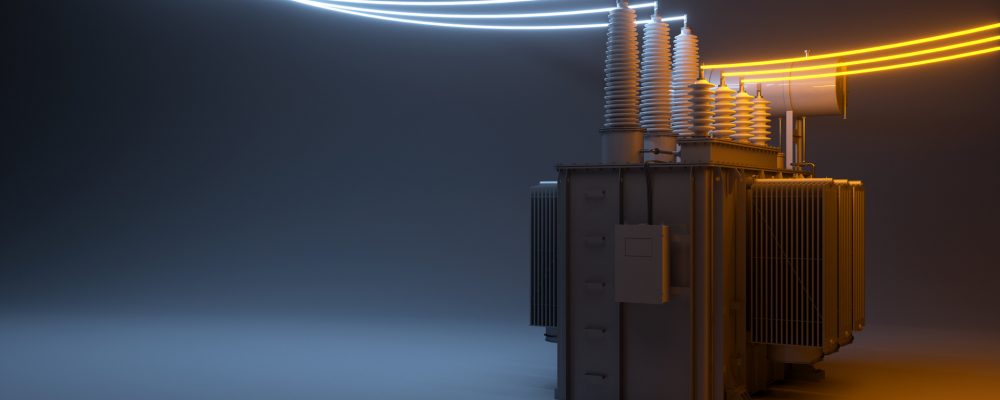

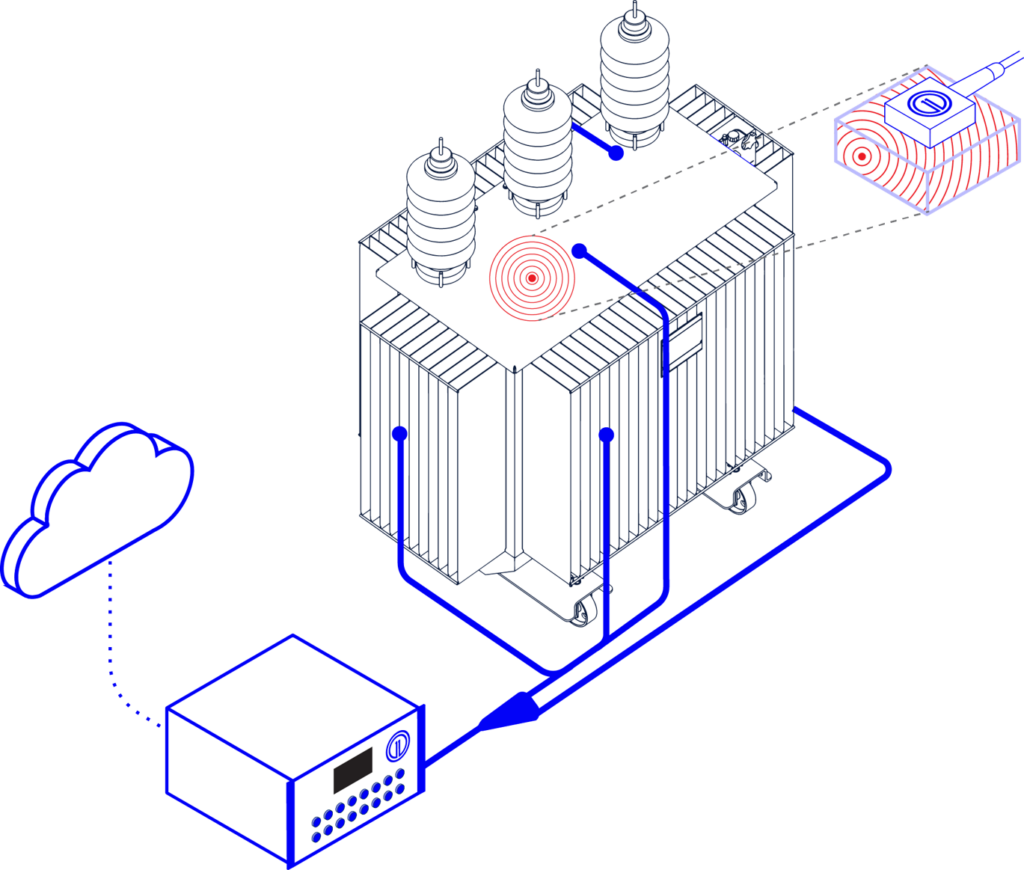

At Optics11, partial discharge (PD) monitoring of electrical assets is one of our focus areas. This is why, we offer OptiFender, our innovative partial discharge monitoring system. It allows the business to save money by catching early signs of potential faults and preventing them early. The importance of condition monitoring as a whole, and partial discharge monitoring in particular, is more crucial than ever.

As we know, partial discharge appears in various electrical assets, and power transformers as well. Therefore, PD acts as the early warning signals within power transformers and indicates the onset of potential failures. This is why regular and precise PD monitoring is important for today’s energy landscape.

Reasons for Partial Discharge Monitoring

Let’s dive into the reasons why PD monitoring is important.

- Heavier Grid Loading. Certainly, as our demand for energy grows, and age of assets increases, PD appears more and more often.

- Preventative Maintenance. A robust PD monitoring strategy ensures that early PD signs are detected well before they develop into major problems.

- Reduction of Unplanned Outages. Indeed, unplanned outages represent a huge economic loss and reliability issues. Through PD monitoring predicts such outages.

- Grid Modernization. As we modernize our grid, integrating new technologies, the complexity of managing PD only increases. A modern grid demands modern monitoring solutions.

- Safety Concerns. Above all, PD monitoring is critical in preventing accidents and ensuring that our power systems are not just efficient but also safe.

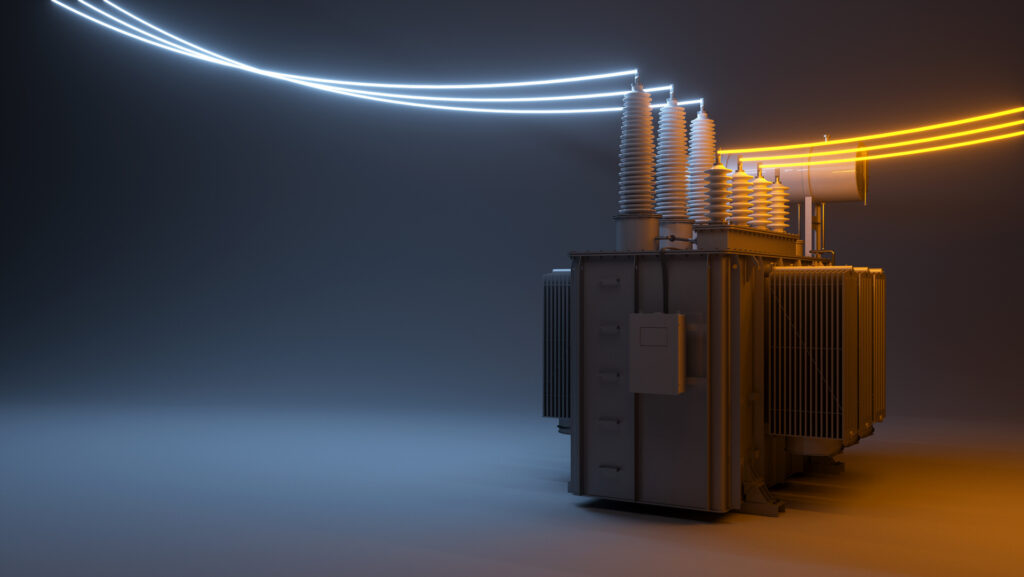

Financial Implications: A Reality Check

Speaking of financial implications, based on “Transformer Reliability Survey – Tutorial of CIGRÉ WG A2.37,” over 31% of power transformers are scrapped after failures. And often, PD leads to such catastrophic failures.

Generally, the replacement cost of a large transformer of 100 MVA ranges from €200 000 to over €1 million. At the same time, the repair cost varies from €20 000 to €500 000 or more, depending on the extent of the damage and the cost of the components. Lastly, there are indirect cost of transformer failure: system downtime, lost revenue, and potential penalties for interrupted service. So, indirect costs sometimes exceed the direct costs of repair or replacement, adding up to several millions of euro.

The message is clear: the time for proactive transformer health management is now. OptiFender helps you avoid multi-million losses, keeping your electrical assets continuously monitored.

Learn more about OptiFender and it’s unique capabilities in our latest webinar with experts from Optics11: Webinar: Mastering PD Localization in Transformers with OptiFender – OPTICS11 Fiber Optic Sensing Solutions (wpengine.com)

Download OptiFender materials to familiarize yourself with our PD monitoring system here