Factory acceptance test (FAT) is a crucial phase in transformer manufacturing process. It ensures that each unit meets quality standards before shipment. During one of our webinars, we highlighted the role of OptiFender during IVPD test in a case when PD is detected. We talked about OptiFender’s ability to detect and localize partial discharges (PD) efficiently, cutting required testing time.

According to the IEC 60076-3 standard, there are several phases of testing the transformer and its health. One of the tests is a long-term induced voltage withstand test of winding and bushing with partial discharge (PD) measurement. In some cases, PD occurs in transformer, and that leads to thorough investigation to localize the source and further fix the issue. OptiFender comes in handy to locate the PD source quickly if transformer shows signs of PD.

OptiFender localized PD source during FAT in 6 hours

Considering the size of the transformer, localizing the PD source can take up to several days if done in a traditional way. However, OptiFender cuts this time down to 6 hours – the result we achieved in one of the factory acceptance tests we ran in 2023.

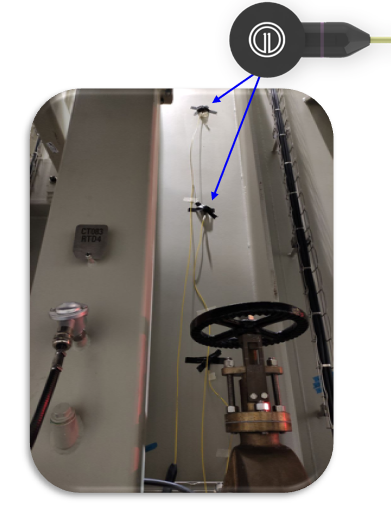

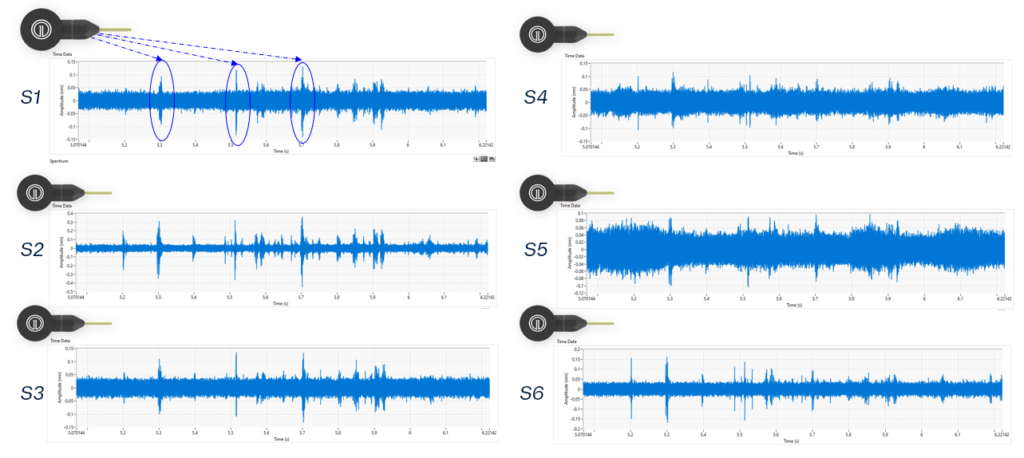

This particular case involved a transformer that exhibited issues around one of its phases. The unit was energized up to 130% of its nominal voltage to simulate operating conditions. During this test, we employed six fiber optic sensors distributed around the suspected phase. This setup allowed for immediate detection of partial discharges, evident from the signal amplitudes captured over time. Multiple peaks in the graphs below indicate the presence of PD picked up by each of the sensors.

Moreover, the observed partial discharge source moved, indicating floating particles in the transformer oil. OptiFender’s data analysis tools simplified the diagnostic process and swiftly identified location of the source. Physical check of the transformer later on confirmed that PD source was located correctly.

A clear advantage of OptiFender is its capability to handle up to 32 sensors at once. This high sensor capacity and possibility of retrofit reduces the installation time of OptiFender. OptiFender is intrinsically immune to electro magnetic interference, which makes it a perfect fit for high and medium voltage environments.

In conclusion, OptiFender not only minimizes the time required for factory acceptance test but also enhances the quality of data analysis, leading to quicker resolutions and higher confidence in transformer reliability. Its deployment in factory settings shows our commitment to delivering advanced monitoring solutions that keep pace with the evolving needs of the energy sector.

Learn more about OptiFender for transformers here by downloading our brochure