Acoustic emission testing is one of the non-destructive techniques Optics11 AE system OptimAE can be used for. The acoustic emission principles however often get confused with the acoustic testing ones.

What are the differences between the two and why are they not the same thing?

Acoustic testing is the measurement of sound, noise and vibration. When we talk about acoustic testing, we imply frequencies inside the audio band <20kHz. You might be interested in doing acoustic testing to identify high level noise or vibrations.

Acoustic emission testing, on the other hand, is done above the audio band >20kHz and serves a specific purpose of detecting damages and defects in materials. It is a non-intrusive and flexible technique that can be applied in a variety of situations:

- Structural Health Monitoring

- Integrity assessment

- Leakage detection

- Material characterization

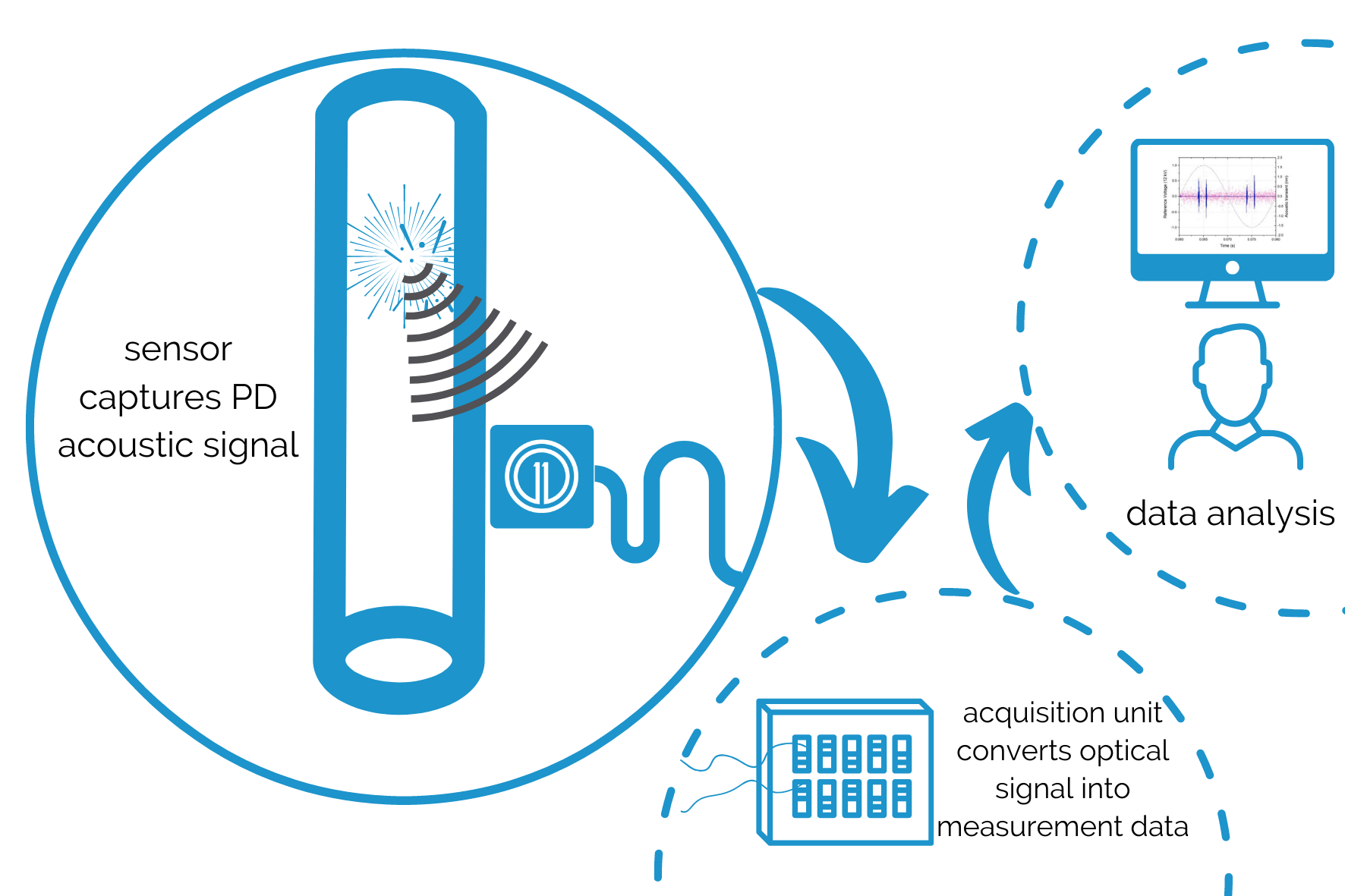

- Partial discharge detection

Optics11 system – OptimAE, is a revolutionary new way of measuring acoustic emission signals. OptimAE is based on fiber optic measurement principles without any compromise on the sensitivity as offered by state-of-art electric AE sensing systems. OptimAE acquires its signals by coupling acoustic emission fiber-based sensors to a surface of a component or structure you would like to monitor. Whenever a defect appears, this event generates a high-frequency wave that the sensor will capture and convert in real time into an AE event. For example, when used for structural health monitoring, sensors that are placed on the structure will continuously monitor the structure actively listening to dynamic changes of the material. If small faults appear (e.g. cracks forming inside the structure), sensors that are placed on the surface will detect these events even before they become visible to the human eye. You will not need to worry about placing the sensors outside or using them in harsh conditions like extreme temperatures, radiation or harsh weather conditions – fiber optic sensors are completely passive, immune to electromagnetic interferences and their performance will stay intact for decades.

Ultimately, acoustic emission testing allows you to monitor condition of materials and detect potential damages at an early stage. Learn more about OptimAE here or contact our sales team with your specific application.