Introduction

In the complex world of power transmission, ensuring consistent electricity supply to urban and industrial areas is a top priority for utility providers. The concept of Partial Discharge (PD) sensing is gaining attention as a critical tool in this area. The big question is: What can proactive PD sensing really do, and how does it change the way we think about maintenance and managing power lines? Let’s dive into this topic and uncover its various aspects.

Taking a New Approach to Prevention – The Role of PD Sensing

In the vast field of power transmission and distribution, PD sensing has become more than just an impressive technology. It’s now a key part of preventive maintenance.

Making Preventative Maintenance Easier

PD sensing gives a clear picture of the condition of electrical insulation in power systems, revealing problems before they lead to major issues. This approach serves two major purposes – it avoids unexpected shutdowns and helps prevent large-scale power outages.

Planning Downtimes Smartly

PD sensing enables utility companies to schedule maintenance at the right times, reducing surprise disruptions. Scheduled maintenance, guided by PD sensing data, is more efficient and less disruptive to customers.

Focusing on Specific Areas – Localized Measurements and Targeted Action

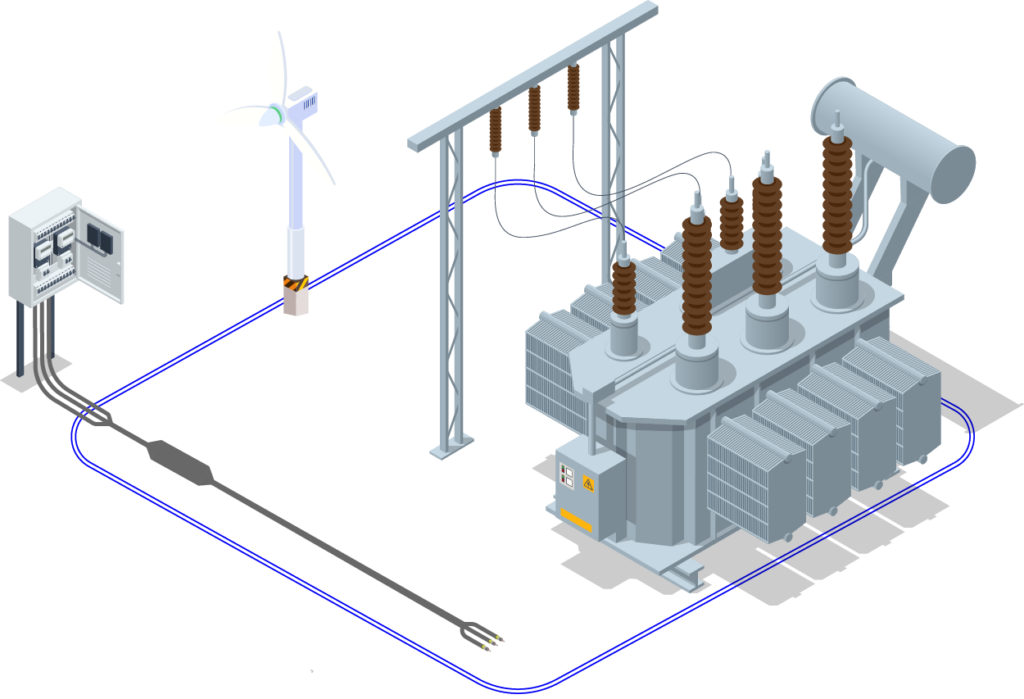

PD sensing also plays a crucial role in identifying specific problem areas within the transmission network.

Identifying Key Problem Areas

With PD sensing, engineers can pinpoint specific parts of the transmission line, like joints or terminations, that might fail. This precise approach avoids the need for large-scale shutdowns.

Choosing Proactive Over Reactive Strategies

While reactive strategies might seem simpler, a closer look at the costs shows why proactive strategies are better.

Saving Money with Preventative Actions

Preventative measures, enabled by PD sensing, are generally cheaper than fixing things after they break. Studies often show a clear cost difference between ongoing monitoring, complete cable replacements, and emergency repairs after a failure.

Balancing Costs and Operations

So, PD sensing is not just about technology. It’s also about finding a balance between spending money wisely and keeping operations running smoothly.

Conclusion

In the world of power transmission, PD sensing is a crucial guard against failures, ensuring a steady flow of electricity. It combines technical skill with strategic planning, making maintenance more effective, scheduling downtime wisely, and focusing on the right areas for repairs.

PD sensing is not just about preventing technical issues. It also brings operational efficiency, cost savings, and better customer service. As utility providers plan for the future, incorporating PD sensing is essential. It paves the way for a future with uninterrupted power and proactive handling of potential issues.

For more insights and assistance in integrating PD sensing into your operations, don’t hesitate to contact our team at Optics11. We are here to guide you through this transformative journey in power transmission.