High frequency acoustics

Acoustic sensing for partial discharge monitoring

The world’s first passive PD monitoring solution

Overview

The significance of fiber optic acoustic sensing

With applications ranging from structural health monitoring to medical imaging, acoustic sensing is currently a very demanding field that is crucial to modern society. Fiber optics can provide a variety of benefits, and fiber optic acoustic sensors have already demonstrated performance levels competitive with those of traditional piezoelectric transducer-based sensors.

Immune to electro magnetic interference

Monitoring of remote assets (> 20km)

Galvanically isolated sensors for easy installation

Completely passive – no power at sensing location required

Meet OptiFender

OptiFender: The World's First Fiber Optic Discharge Monitor.

OptiFender is the world’s first fiber optic partial discharge monitoring system.

Its unique patented technology delivers a high reliable fiber optic solution, while keeping the same performance as state-of-the-art electrical systems.

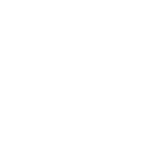

OptiFender includes:

- Modular acquisition unit

- Fiber optic PD sensors

- Magnetic clamp

- Dedicated software package

OptiFender

Validated both in a lab setting as well as in the field

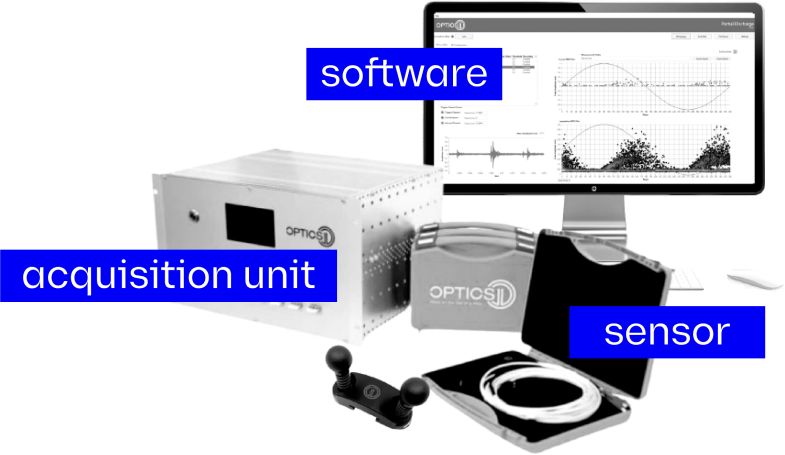

Monitoring for transformers

Passive Fiber Optic PD Sensor for Accurate Monitoring

OptiFender measures the acoustic emission signals of partial discharges and tracks their evolution over time with fiber optic PD sensors. The measuring principle behind the fiber optic PD sensor is based on the acoustic emission technology.

The small and completely passive sensors can be easily installed on any kind of asset, enabling the detection of close-by internal and surface partial discharges.

The acoustic emission signals acquired by the sensor is transmitted to the acquisition unit through a standard telecommunication optical fiber. The acquired data is then displayed and analyzed through the dedicated software.

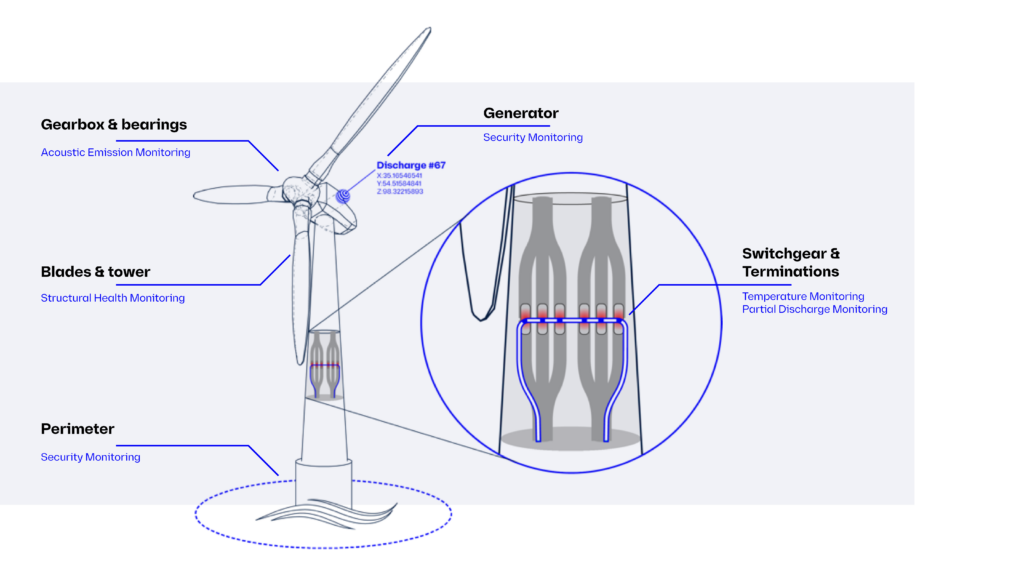

Monitoring for wind turnines

Real-time status monitoring & preventative maintenance of wind turbines

Real-time status monitoring and preventative maintenance of wind turbines have been dramatically improved through the use of fiber optic sensing technology. This technology allows for continuous, real-time monitoring of various crucial aspects of a turbine’s performance such as structural integrity, temperature, vibration, and strain. By using fiber optic sensors, operators can detect anomalies in wind turbine operation, thereby allowing for immediate corrective action, or even predictive maintenance, to prevent costly and potentially dangerous failures. This way, the overall operational efficiency and lifespan of the turbines are significantly enhanced. The sensors, being immune to electromagnetic interference and adverse environmental conditions, are ideal for the challenging environments in which wind turbines typically operate. This fusion of digital monitoring and preventative maintenance signifies a significant leap forward in wind energy technology, driving its evolution towards increased reliability and sustainability.

Fiber optics vs. electrical systems

Measuring internal Partial Discharge (PD) down to 10 pC

Our revolutionising technology allows us to detect even the slightest indications of PD. Our success is not only demonstrated through the work we do with our clients but through our peer-reviewed research as well.

OptiFender benefits

EMI immunity

- Completely passive transducer

- Crystal clear signal in any environment

- Consistent measurements and reliable data

Remote locations

- Acquisition unit and sensors can be spaced tens of kilometres apart

- Monitoring of remote HV assets

- Simple cabling to cover long distances

Easy installation

- Uninterrupted equipment operations during installation

- Safe, galvanically-isolated sensor

- No technically complex training needed

- Small and lightweight sensor

No power required

- No pre-amplifiers needed

- Fiber optic sensors do not require any electrical power

Equipment

OptiFender data acquisition unit

The data acquisition unit is a modular readout that transmits and receives the optical signal from the sensor.

OptiFender data acquisition unit

The data acquisition unit is a modular readout that transmits and receives the optical signal from the sensor.

OptiFender data acquisition unit

The data acquisition unit is a modular readout that transmits and receives the optical signal from the sensor.

“OptiFender allowed us to solve the main limitations and now we are able to benefit from long-distance coverage and EMI immunity. After trying out of the first OptiFender system, we were happy about the results and proceeded to use OptiFender for a number of current projects,”

- I. Matychenkov

Enhance Your Power System Reliability with

Finer Optic Partial Discharge Monitoring System

Our system provides accurate and reliable data on your power system’s performance. Monitor partial discharges in real-time to detect potential problems early and prevent costly downtime. Download our brochure now.