OptimAE

Acoustic Emission Monitoring

An acoustic emission monitoring system for energy storage facilities.

Overview

Detect and monitor partial discharge using fiberoptics

OptiFender is an innovative fiber optic sensing solution which enables partial discharge monitoring of high voltage assets in challenging environments.

Thanks to its unique fiberoptic technology and passive sensing principle, the OptiFender system delivers a set of benefits for your most challenging installations:

Immune to electro magnetic interference

Monitoring of remote assets (> 40km)

Galvanically isolated sensors for easy installation

Completely passive – no power at sensing location required

Critical monitoring for HV & MV assets

OptiFender allows you to localize PD source in an asset remotely and in real time

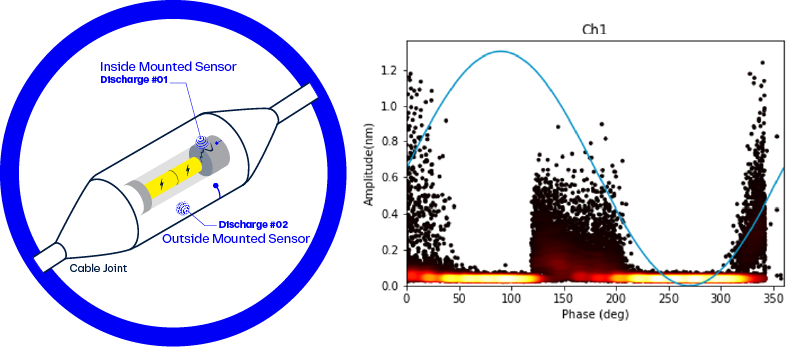

HV Cable Accessories

Monitor the PD in HV and EHV cable joints and terminations by retrofitted or embedded sensors.

Switchgear

Detecting partial discharge in switchgear is crucial for the maintenance and operation of gas-insulated substations (GIS) and gas-insulated lines (GIL).

Transformers

Diagnose and monitor transformers to identify and localize PD source.

HV/MV inverter fed machines

Detect partial discharge in electrical machines in real time.

What is OptiFender

OptiFender: The World’s first fiber optic based partial discharge monitoring system

OptiFender is the world’s first fiber optic partial discharge monitoring system.

Its unique patented technology delivers a highly reliable fiber optic solution, while keeping the same performance as state-of-the-art electrical systems.

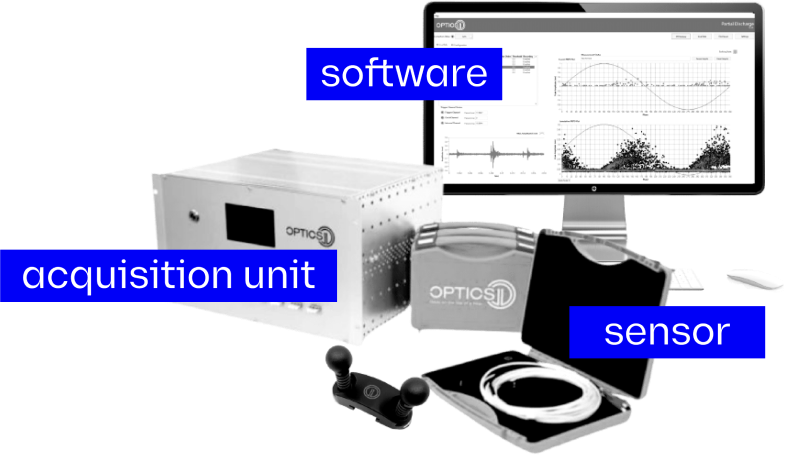

OptiFender includes:

- Modular acquisition unit

- Passive fiber optic PD sensors

- Magnetic clamps and installation accessories

- Dedicated software package

How does it work

Passive Fiber Optic PD Sensor for Accurate Monitoring

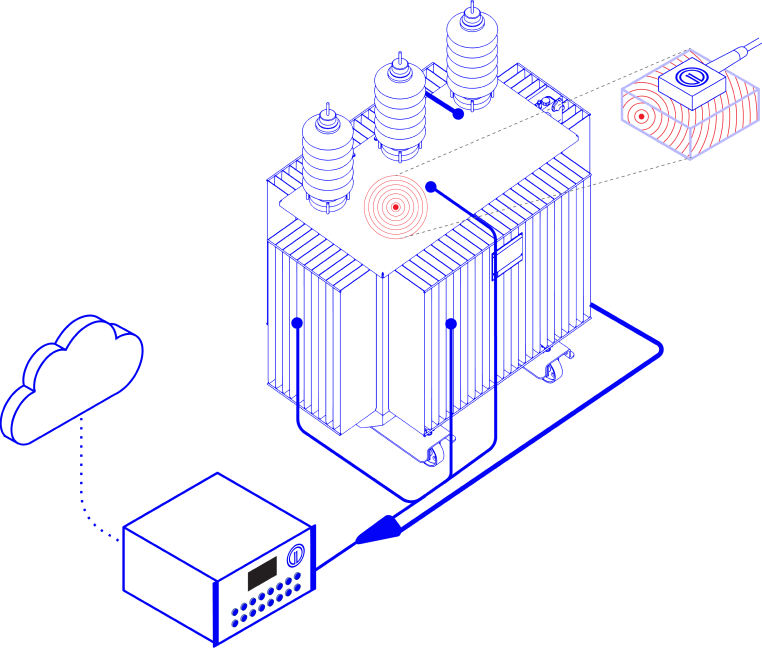

OptiFender measures the acoustic emission signals of partial discharges and tracks their evolution over time with fiber optic PD sensors. The measuring principle behind the fiber optic PD sensor is based on the acoustic emission technology.

The small and completely passive sensors can be easily installed on any kind of asset, enabling the detection of close-by internal and surface partial discharges.

The acoustic emission signals acquired by the sensor is transmitted to the acquisition unit through a standard telecommunication optical fiber. The acquired data is then displayed and analyzed through the dedicated software.

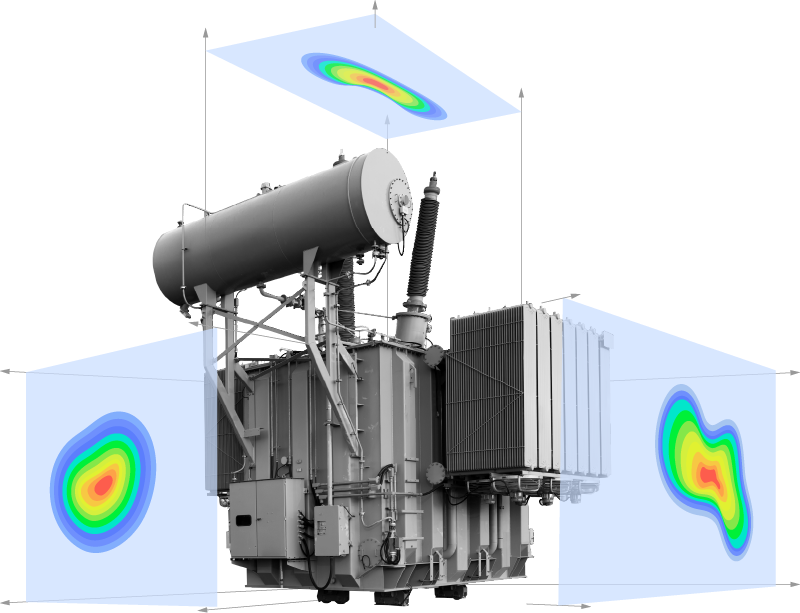

Localization

Partial Discharge Localization

The OptiFender® system enables the precise localization of Partial Discharge (PD) sources with accuracy down to the centimeter level.

Harnessing this high-precision capability, OptiFender® empowers maintenance teams to effectively identify and prioritize critical areas for intervention, ensuring optimal transformer health and longevity of the affected components.

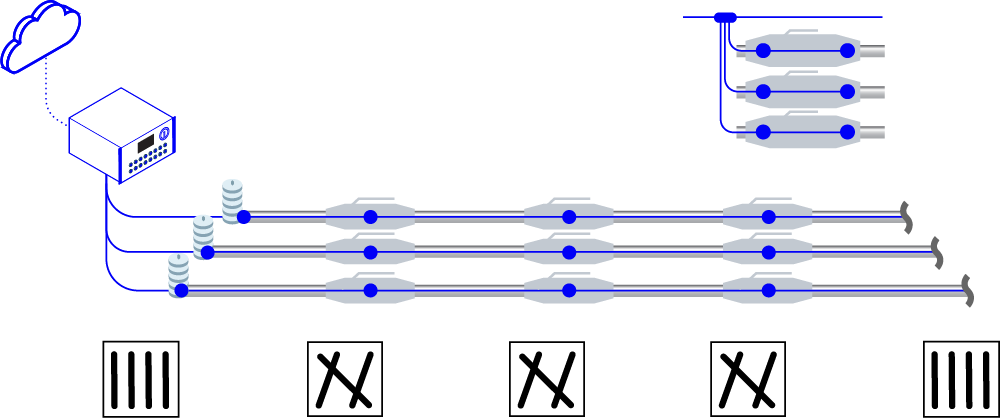

Daisy Chaining

Efficient Monitoring with Daisy-Chain Capabilities

The OptiFender® system introduces a streamlined approach to monitoring with its innovative daisy-chaining capability.

By allowing multiple sensors to be interconnected along a single fiber optic line, it simplifies the setup while extending the monitoring reach. This setup can be strategically managed from the substation control room, where the acquisition unit centralizes data from sensors located even kilometers away.

Utilizing standard telecommunication optical fibers, the system offers a seamless, robust connection that ensures real-time data acquisition and analysis. With the ability to monitor a substantial number of sensors through a single acquisition unit, OptiFender® sets a new standard for efficiency and reliability in the field of asset monitoring.

How does it compare to an electric system

Measuring internal Partial Discharge At PDIV and PDEV

Our revolutionising technology allows us to detect even the slightest indications of PD. Our success is not only demonstrated through the work we do with our clients but through our peer-reviewed research as well.

What OptiFender offers

EMI immunity

- Completely passive transducer

- Crystal clear signal in any environment

- Consistent measurements and reliable data

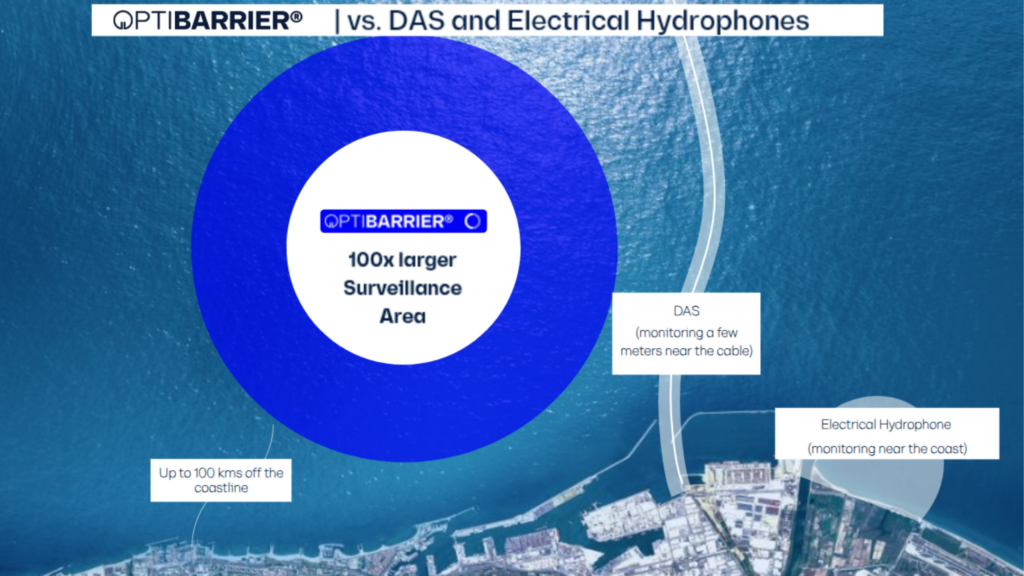

Remote locations

- Acquisition unit and sensors can be spaced tens of kilometres apart

- Monitoring of remote HV assets

- Simple cabling to cover long distances

Easy installation

- Uninterrupted equipment operations during installation

- Safe, galvanically-isolated sensor

- No technically complex training needed

- Small and lightweight sensor

No power required

- No pre-amplifiers needed

- Fiber optic sensors do not require any electrical power

Equipment

OptiFender data acquisition unit

The data acquisition unit is a modular readout that transmits and receives the optical signal from the sensor.

OptiFender sensors and accessories

The sensors detect and measure the acoustic emission (AE) from partial discharges by fiber optic sensing technology.

OptiFender data interpretation

Analyzing the signals from the sensors, the measured signals are converted into meaningful insights, such as time domain, frequency domain, PRPD, and PD localization results.

Questions and Answers

FAQ

PD (Partial Discharge) monitoring helps prevent unplanned downtime, avoiding revenue loss, regulatory fines, increased insurance premiums, and damage to a utility company’s reputation by identifying potential high voltage assets failures before they occur.

Within the domain of HV equipment testing, commissioning, and operation, PD monitoring plays a pivotal role, ensuring adherence to rigorous performance and standard specifications. By meticulously identifying and addressing defects during the design and production phases, it allows OEMs to deploy impeccably crafted equipment. This proactive approach significantly reduces the risk of field failures and minimizes potential warranty claims, ensuring a seamless and reliable engineering solution.

PD sensing plays a crucial role in predictive and preventative maintenance, as well as in system reliability. PD monitoring enhances power system reliability through the early detection of potential failures. It helps prevent catastrophic failures, facilitates predictive maintenance, and extends the life of assets.

Yes, a failure, especially in HV and EHV systems, can stress redundant cable systems and generation sites, potentially causing cascading issues across the network and necessitating rapid emergency response to prevent widespread asset damage.

The OptiFender solution for PD sensing is applicable to all voltage levels from MV to EHV without impacting the implementation cost of the system. This becomes especially advantageous for HV and EHV systems, as traditional PD monitoring solutions tend to become exponentially more costly as the voltage level increases.

Implementing PD sensing for vital assets and HV equipment is a key element in a comprehensive preventative maintenance strategy. While conventional tools like current, voltage, and temperature sensing are valuable, they lack the accuracy provided by PD monitoring. Integrating PD sensing is essential for a detailed evaluation of asset health, guaranteeing a robust and forward-thinking maintenance approach.

OptiFender offers numerous advantages, such as cost-effectiveness across various voltage levels, adaptability to different voltage levels, accurate PD localization capabilities, retrofitting features, passive sensors that don’t need power at the sensing location, immunity to EMI and electrical background noise, long-distance operation, and precise PD sensing, allowing for immediate identification of the PD source in HV and EHV assets.

“OptiFender allowed us to solve the main limitations and now we are able to benefit from long-distance coverage and EMI immunity. After trying out of the first OptiFender system, we were happy about the results and proceeded to use OptiFender for a number of current projects,”

- I. Matychenkov