Overview

Your gateway to meaningful results

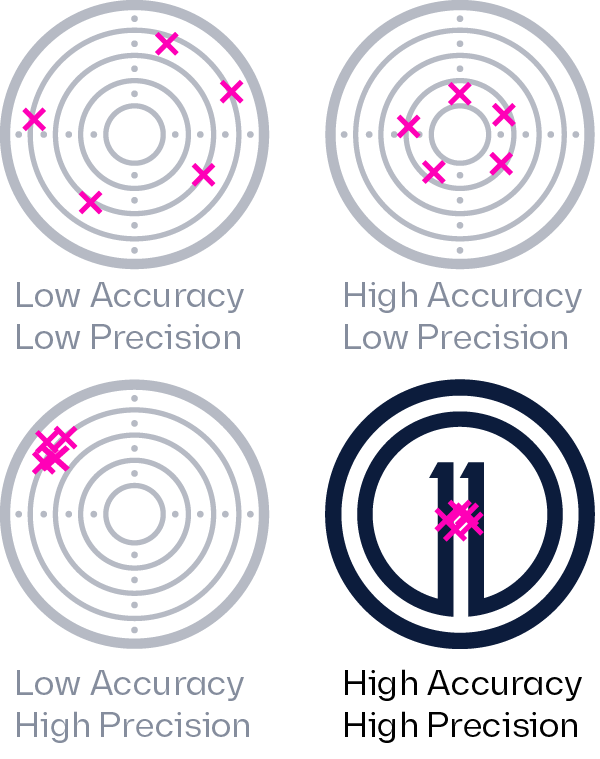

Fiber optic FBG sensing is a well-established technology which provides a monitoring solution in challenging conditions where electric sensors have difficulties delivering. Nevertheless, existing optical sensing systems still struggle in delivering reliable solutions in many applications, limited by their noise performance and the lack of long-term stability.

The I4 series FBG interrogators provide the ultimate solution for all your fiber optic sensing projects. Providing unmatched precision, noise-floor, and accuracy, the I4 series deliver the performance that all sensing systems require to turn into a reliable monitoring solution.

Equipment

I4G FBG interrogator

The NovaFAZ I4G FBG interrogator delivers precision and adaptability in a 4-channel instrument for diverse applications, featuring high-speed data acquisition and exceptional optical range.

I4W FBG interrogator

I4W is the economy model of the series, offering many of the excellent features of the flagship model in a cost-effective 4 channel system (up to 120 sensors).

I4-16 FBG interrogator

I4-16 combines the core technology of the flagship model I4G together with a high-reliability optical switch to create a 16 channel Interrogator (up to 480 sensors).

Benefits

A Turn-key solution for all your projects

Whether you are dealing with dynamic or static measurements, with R&D projects or large in-field installations, the I4 series offers all you need to stop worrying about your measuring system reliability and to start acquiring meaningful data.

The I4 series offer a complete hardware and software suite, easy to setup and integrate in existing control or monitoring systems.

Scan-by-scan calibration

A gas reference cell is used to calibrate the interrogator readings of each laser sweep, ensuring absolute accuracy and long-term reliability.

Dynamic gain

Adjustable gain for each FBG allowing maximizing the SNR of all sensors connected along a fiber, regardless of their reflectivity.

Ultra-low flat noise floor

The I4 series features the lowest noise floor available in the market from DC to 4 kHz, ensuring ultimate performance for both dynamic and static measurements.

Dynamic regions

A smart peak-tracking algorithm allows tracking of FBG peaks regardless of temperature drifts, making sure your sensors are reliably monitored in all conditions.

Patented FBG technology.