What is ExpertHub?

Pinpoint partial‑discharge defects in hours, not days—and finish Factory Acceptance Tests on schedule.

Instant, high‑resolution PD insights from passive, EMI‑immune fiber‑optic sensors give your team the confidence to sign off faster, slash FAT costs, and protect critical assets without constant sensor shuffling or calibration.

Benefits

Why ExpertHub?

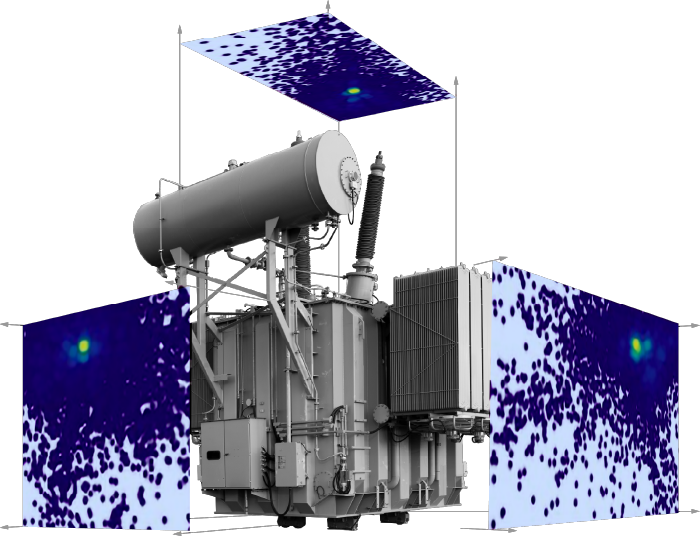

One‑pass, 3‑D localization

Up to 32 ORPD 040 sensors capture the whole asset at onceStable gain & wide dynamic range

Maintenance free, no recalibration needed.Deep data access (TDMS)

Save raw waveforms for root‑cause analysis and model validationAccelerated FAT workflow

Cut repetitive repositioning, retesting, and idle time

Your Benefits

Laboratory‑Grade PRPD Data

ExpertHub streams high‑resolution, phase‑resolved partial‑discharge (PRPD) patterns in real time, delivering the raw evidence your specialists need for confident, standards‑compliant analysis.

Faster, Targeted Repairs

On‑board triangulation pinpoints defects before energization—no shutdowns or follow‑up site visits.

Lower Total FAT Cost

Passive fiber optics mean zero calibration or batteries. Fewer re‑tests and shorter dwell times slash labor, crane, and floor‑space charges.

Clean, Noise‑Free Signals

EMI‑immune sensors capture pristine waveforms—even inside high‑voltage factories and HV labs.

Deep Insight, Unlimited

Full TDMS files and PRPD plots are archived automatically, ready for your in‑house tools, model validation, and future audits.

24 × 7 Oversight

Leave ExpertHub connected for burn‑in or extended soak tests to catch emerging issues before shipment.

Localize partial‑discharge defects precisely in a single work‑shift. Eliminate re‑runs, minimize downtime, and keep every FAT on track.

Capabilities

- Immunity to Electromagnetic Interference (EMI)

- Passive Operation with No Power Requirement at the Sensing Location

- High Sensitivity for Early Detection

- Non-metallic Sensors

- Immediate Partial Discharge (PD) Localization Without the Need for Expert Insight

- Long Sensor Life

- Easy Integration or Retrofitting Capability

How does it work

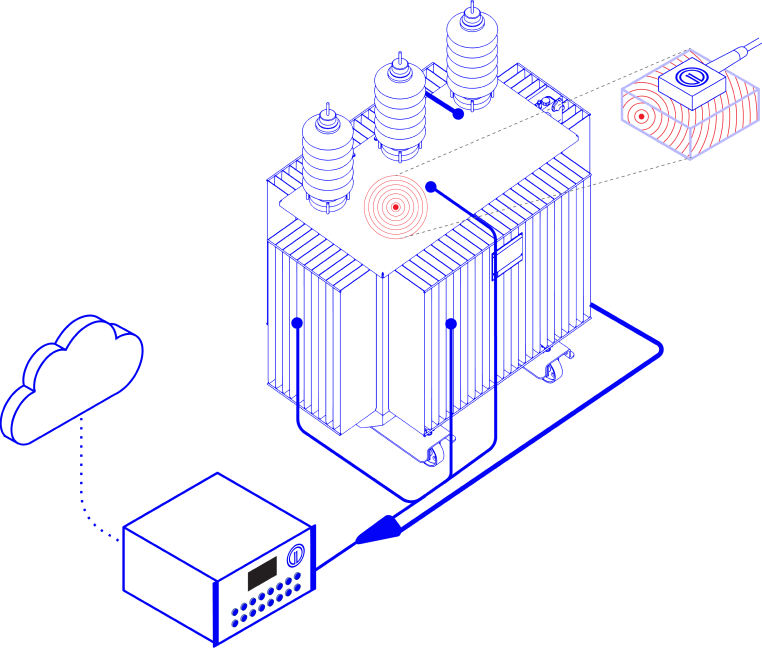

Passive Fiber Optic PD Sensor for Accurate Monitoring

OptiFender measures the acoustic emission signals of partial discharges and tracks their evolution over time with fiber optic PD sensors. The measuring principle behind the fiber optic PD sensor is based on acoustic emission technology.

The small and completely passive sensors can be easily installed on any kind of asset, enabling the detection of close-by internal and surface partial discharges.

The acoustic emission signals acquired by the sensor is transmitted to the acquisition unit through a standard telecommunication optical fiber. The acquired data is then displayed and analyzed through the dedicated software.

PD Localization

Partial Discharge Localization

The OptiFender system enables the precise localization of Partial Discharge (PD) sources with accuracy down to the centimeter level.

Harnessing this high-precision capability, OptiFender empowers maintenance teams to effectively identify and prioritize critical areas for intervention, ensuring optimal transformer health and longevity of the affected components.

Software

OptiFender for Windows — Expert PD Visualization & Control

See partial-discharge activity come alive in true 3-D while you test. OptiFender’s Windows-based suite streams a live asset view, lets you fine-tune system and sensor settings, set custom alarm thresholds, and instantly export raw TDMS data for deep analysis. From real-time monitoring to precise 3-D localization, every tool is built in. Start diagnosing with lab-grade clarity.

OptiFender ExpertHub Product Tiers at a Glance

ExpertHub Lite | ExpertHub Pro | ExpertHub Ultra | |

|---|---|---|---|

PD Location Time | Up to 8 h if multiple repositionings are needed | ~ 4 h on a mid-sized asset | ≤ 4 h on any asset—single-pass

|

Tests Required to Localize | 1 – 5 tests | 1 – 2 tests | 1 test |

Best-Fit Scenario | Budget-friendly spot checks where repeat runs are acceptable | Balanced choice: cut downtime by covering more area in one go | Mission-critical assets that demand near-certain PD detection in one deployment |

Stand-out Strength | Compact, easy-to-deploy PD detection | Wider sensor net for thorough fault pinpointing | Maximum sensor density for highest diagnostic confidence |

Operation & Coverage | 4 sensors — may need repositioning on larger assets | 16 sensors — covers larger zones simultaneously | 32 sensors — full-asset, real-time monitoring |

Ideal Use Cases | Small assets or larger units where moving sensors is feasible | Mid-sized or multiple assets with one-time sensor placement | Large-scale or intricate systems needing ultra-accurate, one-pass results |

How does it compare to an electric system

Measuring internal Partial Discharge At PDIV and PDEV

Our revolutionising technology allows us to detect even the slightest indications of PD. Our success is not only demonstrated through the work we do with our clients but through our peer-reviewed research as well.

PD Expert Report

Actionable Insights at Your Fingertips

We believe in making complex data understandable. Our custom reports are not just detailed but also easy to comprehend, helping you make informed decisions about your assets. With Optifender MaaS, you get the results without the hassle.

Remember, with Optifender MaaS, you’re not just getting a service, you’re gaining a partner committed to the longevity of your infrastructure. Let us handle the complexities of PD monitoring while you focus on what you do best.

Questions and Answers

FAQ

OptiFender ExpertHub slashes costs by completing FATs in a single four-hour pass, eliminating extra labor, crane time, and bay fees; its passive fiber-optic sensors never need calibration or batteries, so you avoid recurring maintenance and consumables; one compact sensor type replaces multiple probe sets, cutting hardware and logistics expenses; and the same system can be redeployed for in-service monitoring, spreading a single capital outlay across the asset’s entire life-cycle.

ExpertHub’s rapid, one-pass PD localization flags emerging insulation faults long before they turn into outages, letting you schedule repairs instead of scrambling through unplanned downtime. By shortening FATs and delivering continuous, calibration-free monitoring in service, it shields revenue, avoids regulatory penalties and reputational hits, and keeps insurance premiums in check—all while using a single, maintenance-free sensor platform.

The OptiFender ExpetHub solution for PD sensing is applicable to all voltage levels from Medium Voltage (MV) to Extra High Voltage (EHV) without impacting the implementation cost of the system. This becomes especially advantageous for HV and EHV systems, as traditional PD monitoring solutions tend to become exponentially more costly as the voltage level increases.

OptiFender offers numerous advantages, such as cost-effectiveness across various voltage levels, adaptability to different voltage levels, accurate PD localization capabilities, retrofitting features, passive sensors that don’t need power at the sensing location, immunity to EMI and electrical background noise, long-distance operation, and precise PD sensing, allowing for immediate identification of the PD source in HV and EHV assets.

“As a service company dedicated to maintaining TSO substations, we’ve found the OptiFender product to be an exceptional tool in our arsenal. The process of integrating OptiFender into our workflow was smooth, and the quality of analysis from the PD experts has been consistently high. It’s made a significant difference in how we service substations, providing us with a reliable and effective solution for our TSO clients”

- A Service Company

Ready to shave days off your next Factory Acceptance Test?

Starting with June 2025!

See OptiFender ExpertHub in action.

Book a 30‑minute demo session with one of our specialists and discover how fast,

one‑pass PD localization can compress schedules,cut costs, and raise confidence—without changing the way you test.