Partial discharge (PD) monitoring in a high-voltage operating substation is often associated with plenty of restrictions and hesitation. One might think there is more hassle than benefit. OptiFender proves otherwise. In a recent field test conducted at a 400kV substation in Denmark, OptiFender was deployed to monitor and localize PD in gas-filled cable terminations. Here are the highlights of the process with the main outcomes.

In high-voltage (HV) and extra high-voltage (EHV) systems, it is essential to ensure the reliability and longevity of critical infrastructure like power cables. They play a vital role in electricity transmission, and any failure can lead to significant downtime and costly repairs. We offer OptiFender – our solution to improve monitoring of HV electrical assets based on fiber optic acoustic emission sensing.

The Need for Effective Monitoring

Traditional methods of detecting partial discharge (PD)—a critical early indicator of insulation failure—rely on electrical measurements that are vulnerable to electromagnetic interference (EMI). Generally, electrical measurement systems can be tricky to install. For example, in existing (brown-field) projects, getting to power and proper sensor placement can be challenging.

Fiber optic-based sensors, like in OptiFender, offer an innovative alternative. They are immune to EMI, require no power at the sensing location, transmit data over long distances without signal degradation. So, this makes them particularly suitable for monitoring HV and EHV cable accessories. As we know, PD often occurs in joints and terminations.

PD monitoring with OptiFender: Action

The OptiFender system is designed using interferometric principles, making it highly sensitive to the acoustic emissions produced by PD events. For example, in a recent field test conducted at a 400kV substation in Denmark, OptiFender was deployed to monitor and localize PD in gas-filled cable terminations.

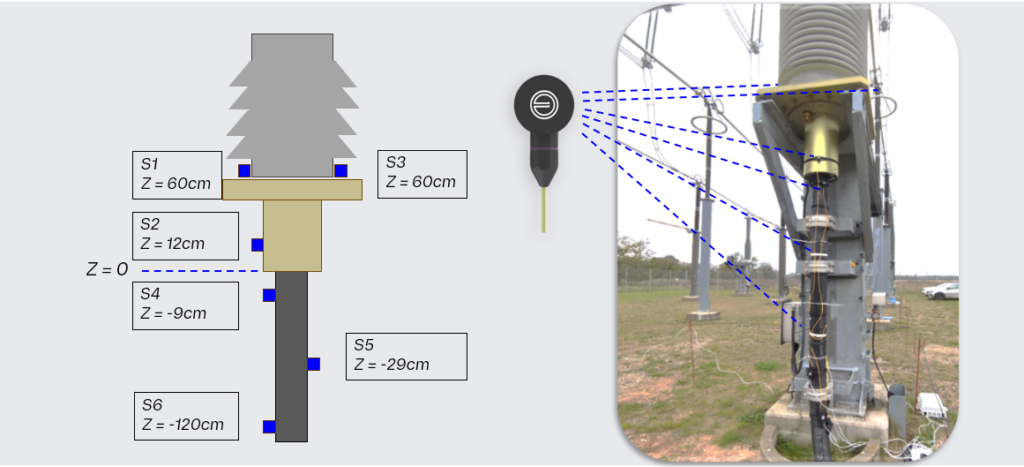

In the field test we focused on identifying the exact location of PD in one of the cable terminations. It had shown signs of intermittent activity in previous measurements. We installed OptiFender sensors on various parts of the termination, including the most suspicious areas and those expected to be PD-free, to serve as references.

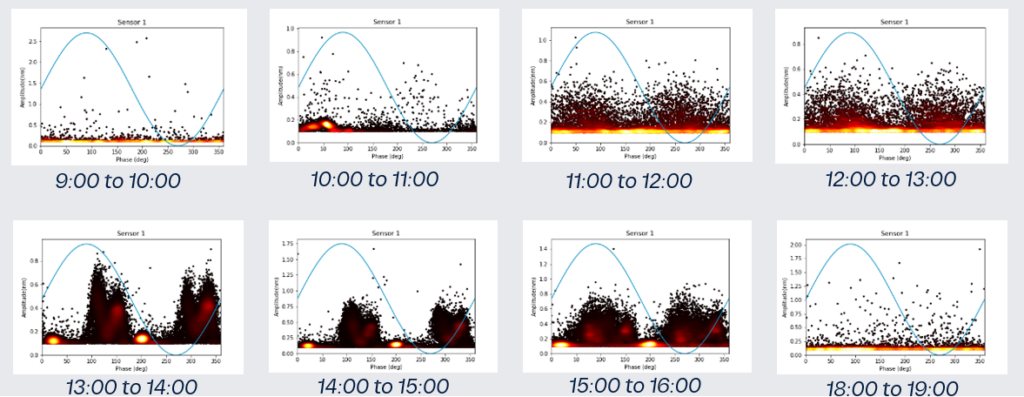

After that, the PD identification was done by looking at the phase-resolved PD (PRPD) patterns and comparing them to patterns from past lab tests with known PD sources. As a result, over 48 hours of continuous monitoring, OptiFender successfully identified PD activity in one of the terminations. The results were consistent with patterns observed in laboratory tests on similar HV and EHV equipment, reinforcing the system’s reliability and effectiveness.

Advantages and Future Applications

OptiFender offers several advantages over traditional PD detection methods:

- High Sensitivity: It can detect PD with greater sensitivity, even in challenging environments.

- Non-Intrusive Installation: Sensors can be retrofitted onto existing equipment without requiring significant modifications or power interruptions.

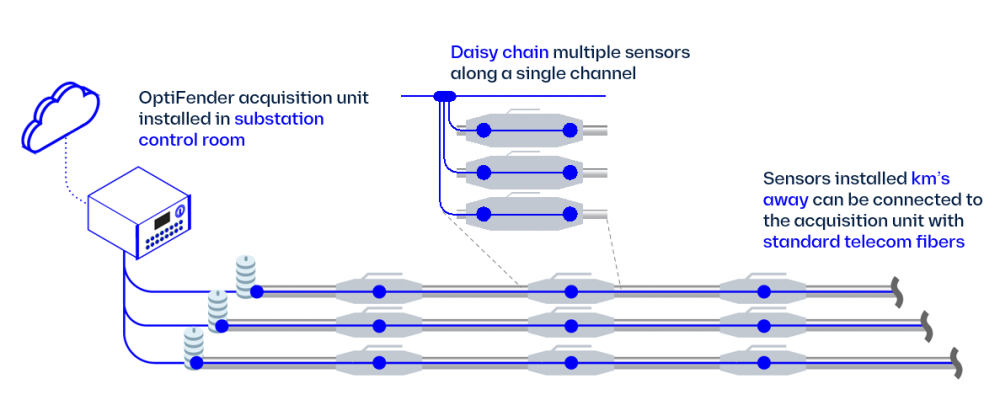

- Scalability: The system supports multiple sensors, allowing for comprehensive monitoring across large HV and EHV networks.

Overall, this field test demonstrates OptiFender’s potential for online monitoring and PD localization in HV and EHV assets. Moreover, as the technology continues to evolve, it plays a crucial role in reducing maintenance costs, preventing failures, and extending the lifespan of critical infrastructure.