The renewable energy industry keeps on growing with wind and solar capacity additions of 13.8 GW in the first 8 months of 2021 alone, that is 28% more than in 2020 according to industry report from Deloitte.

When considering such a fast-paced growth in the wind energy sector, it is important to note that efforts to optimize maintenance are also on the rise as well as efforts to increase the efficiency of each wind turbine.

Fiber Optic Sensing technology helps you get precise data to control gearbox health in real time

Increasingly, wind turbines are using gearboxes with between 3 and 6 planets. One of the ways to improve the maximum torque handling capacity and energy efficiency of a wind turbine is to increase the number of planetary gears inside their gearboxes. However, with higher numbers of planets there is an increase in the fragility of the outer ring gear of gearbox. It also becomes vital to ensure that the loads are distributed evenly across all of the planetary gears to prevent excess wear. If damage to the outer ring gear goes unnoticed up to a critical point, it can result in the need for major and costly repairs and even replacement of elements of the gearbox.

Increase energy efficiency of the wind turbine in a controlled way with NovaFAZ I4G FBG interrogator from Optics11

So here comes the challenge: how to increase energy efficiency in a safe and controlled way to avoid costly repairs and ensure timely maintenance?

Well, the answer to this question is as simple as it can be: data. Getting precise and accurate continuous monitoring data of gearbox health allows the torque experienced by the gearbox to be controlled in real time. This in turn, will allow possibility to avoid exceeding the maximum operating torque and thus increasing the lifetime of the gearbox. As a result, the health of the gearbox is monitored in real-time, allowing for the maintenance to be carried out before unnecessary additional damage is caused.

In this context Siemens Gamesa have begun testing fiber optic monitoring solutions with Sensing360 which allow for a large number of strain and temperature sensors to be added to the gearbox to complement or replace existing monitoring solutions. One of the FBG interrogators from Optics11 – NovaFAZ I4G FBG interrogator was used in the test.

Better feedback of the real-time torque and gearbox health with NovafAZ I4G FBG interrogator

Recent tests performed by Sensing360 and Siemens Gamesa involved the installation of a smart photonic sensing strip on the stationary outer ring of a multimegawatt planetary gearbox. The strip consisted of 48 strain sensors which were placed around the gearbox of the wind turbine measuring the strain distribution around it. Each sensor monitored the strain over several days. Using their gearbox models and Sensing360 algorithms, they then translate these strain signals into crucial engineering and operating parameters such as planet load sharing and torque.

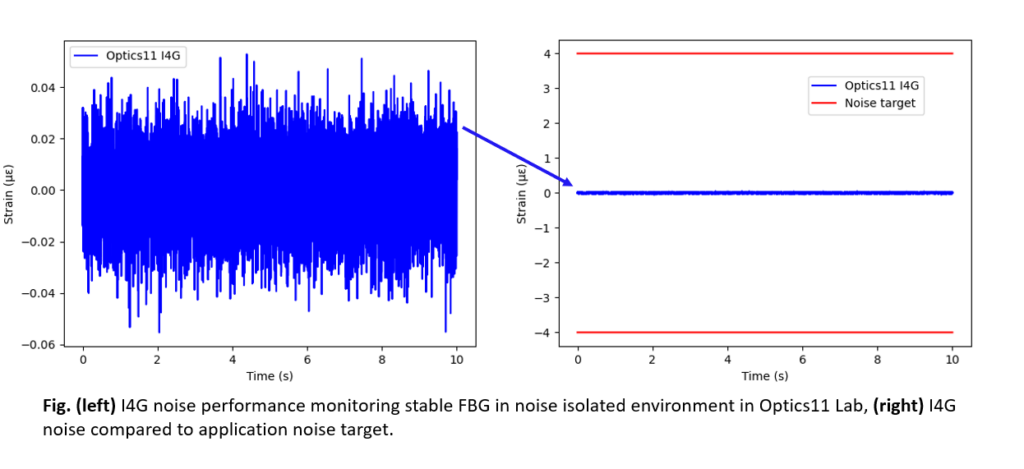

The tests investigated whether reducing the noise of the sensor readout can improve the quality of the feedback provided by the smart sleeve. To test this a series of measurements were set up to directly perform measurements using an NovaFAZ I4G FBG interrogator. The tests proved that NovaFAZ I4G FBG interrogator from Optics11 is delivering unmatched results in precision, repeatability, and accuracy and it exceeded customer expectations based on previous experience with available solutions on the market. This improved interrogator performance has allowed Sensing360 and Siemens Gamesa to further refine their models and have better feedback of the real-time torque and gearbox health.

Achieve low noise floor and great repeatability of the measurement using NovaFAZ I4G FBG interrogator from Optics11

-

Low noise floor

The noise floor was first investigated in a “stand still” not moving measurement. In this test the NovaFAZ I4G FBG interrogator demonstrated >10x reduction in the noise floor compared to the initial target set by the customer before the experiment. This incredible improvement of the performance allows the opportunity to detect exceptionally small signals, improving the precision of all measurements.

-

Great repeatability

Another important factor for making reliable forecasts of asset condition is repeatability of the measurement. Taking measurements of the same sensor in a point of time, day after day, Siemens Gamesa noticed that the repeatability of I4G FBG interrogator allowed highly reproducible measurements over long periods of time. This is essential when looking for long term stability of measurements over extended periods of time.

Improve safety of operation and efficiency of your wind turbine with NovaFAZ I4G FBG interrogator from Optics11

This work has shown the feasibility of having real-time load/torque monitoring using fibre optic sensors incorporated into a smart photonic sleeve. The photonic sleeve allows for many strain sensors to be installed around a gearbox which provides excellent profiling of the strain/temperature generated by the gearbox during operation. Coupling the sleeve with the NovaFAZ I4G FBG interrogator provided unmatched high-quality data. Having the high-quality data enabled by the Optics11 I4G interrogator, allows for the realistic prediction of an asset lifetime, improving the safety during operation time and planning of maintenance before failures occur.

Contact information

NovaFAZ I4G FBG interrogator from Optics11 is a revolutionary new breed of interrogator. Featuring 4 monitoring channels the I4G is the Optics11 flagship FBG interrogator.